| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Shanbao |

| Model Number : | Buhler 660/228 |

| Certification : | ISO 9001:2015 |

| Price : | USD 2000-3000/Piece |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 100UNITS / MONTH |

| Delivery Time : | 20-30 Days |

What is the pellet dies?

Pellet dies are specialized components used in pellet mills, typically in the feed, biomass, and other processing industries. They are essential for shaping and forming the feed material into uniform pellets through a pellet mill. The pellet dies have the below functions:

1. Forming Pellets

The primary function is to compress and shape the feed material into pellets by forcing it through the holes in the die.

2. Controlling Pellet Quality

The design of the die affects the density, size, and durability of the pellets produced, which are crucial for nutritional value and feed performance.

3. Facilitating Uniformity

Consistent hole sizes and spacing in the die ensure that all pellets are uniform in shape and size, which is important for feed efficiency and digestibility.

4. Enhancing Feed Processing:

Properly designed pellet dies can improve the overall efficiency of the pelleting process, reducing energy consumption and wear on the equipment

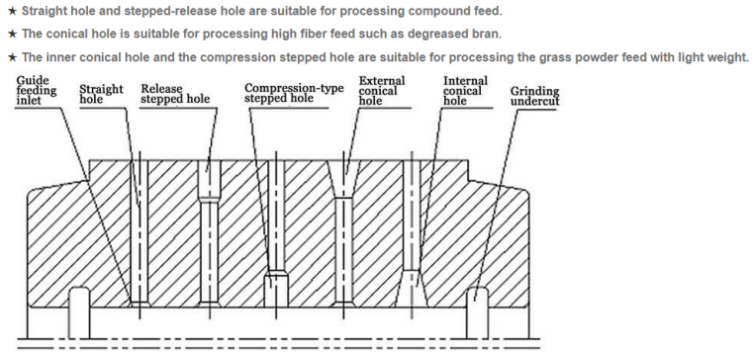

The pattern of the holes:

The hole's pattern will be designed based on the feed ingredients, particle size, PDI, and particle hardness.There are several types of holes, the most common structures of die holes are straight holes, release stepped holes, external conical holes, internal conical holes, etc. Different die-hole structures are suitable for the different raw materials and feed formulas for pelleting.

Compression ratio:

Generally, the higher the compression ratio the denser the finished pellets, but it does not mean the better pellet. The compression ratio should be calculated based on raw materials for pellets and types of feed, buyers can customize dies with different hole diameters and compression ratios according to the situations and requirements.

Shanbao Machinery's advantage:

1. Shanbao Machinery has been engaged to produce pellet mill dies over 30 years and has 3 plants for forging and casting, drilling and fine turning. We're the only dies manufacturer who has its own forging and casting factory in China. We can pround to announce we're the most professional manufacturer in the world.

2. We're a experienced team and have many professional technicians, all of whom have more than 30 years of experience in machinery production.

3. We have some professional after-sales team. When you need, we can come to your factory immediately to solve all problems for you.

4. We are not only produce the pellet mill's parts but we also have some patent machines to expand your parts lifespan. To help you reduce your cost per ton.

5. Shanbao Machinery will help you customize the hole design and structure for your pellet mill dies according to your feed ingredients, particle size and feed formula to achieve higher throughput.

Shanbao Machinery's Pellet Die Application

We have produced many pellet dies for some famous pellet mills, like: CPM, Buhler, Van Aarsen, Andritz, Idah, Matador, PTN, Muyang, SZLH, Famsun,...

| CPM | CPM305 | Buhler | Buhler 35 | MUZL | MUZL 1200 |

| CPM407 | Buhler 40 | MUZL 1210C | |||

| CPM3016-4 | Buhler 42 | MUZL 1610/C | |||

| CPM3016-5 | Buhler 42B | MUZL 35 | |||

| CPM3020-6 | Buhler 508 | MUZL 42 | |||

| CPM3020-6 | Buhler 508E | MUZL 42T | |||

| CPM3022-6 | Buhler 52 | MUZL 460 | |||

| CPM3022-8 | Buhler 530 | MUZL 550 | |||

| CPM7726-7 | Buhler 660 | MUZL 600 | |||

| CPM7726-9 | Buhler 900 | MUZL 600TA | |||

| CPM7730-8 | MUZL 610 | ||||

| CPM7730-10 | MUZL 610TW | ||||

| CPM7936-14 |

| Application | Hole Diameter | Compression Ratio |

| Poultry & Livestock | 2.5-4mm | 1:4-1:16 |

| Fish Feed | 2.0-5.0mm | 1:12-1:14 |

| Shrimp Feed | 0.8-2.0mm | 1:18-1:30 |

| Crab Feed | 4.5-10.0mm | 1:15-1:26 |

| Biomass and Fertilizer | 6.0-8.0mm | 1:4.5-1:8 |

YOU WILL GET MORE TO COLLABORATE WITH SHANBAO MACHINERY!

Application:

Production procedure:

Packing:

Exhibition:

|