| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Shanbao |

| Model Number : | Buhler 520 |

| Certification : | ISO 9001:2015 |

| Price : | USD 100-300/PIECE |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 5000 PCS/Month |

| Delivery Time : | 15-25 DAYS |

Superior Feed Granulator Pressure Roller Shell

Introducing our state - of - the - art feed granulator pressure roller shell, a key component that can transform your feed production process. Made from top - grade materials through advanced manufacturing techniques, this roller shell combines durability and high - performance.

The special alloy composition of the pressure roller shell gives it outstanding resistance to abrasion and corrosion. It can effectively handle a wide range of feed materials, including those with high fiber content or abrasive additives. The optimized structure of the roller shell ensures uniform pressure distribution during the granulation process, resulting in granules with consistent size, shape, and density.

We have also paid great attention to the installation and maintenance aspects of the product. The pressure roller shell is designed for easy installation and disassembly, minimizing downtime during equipment maintenance. Additionally, its reliable performance reduces the overall cost of feed production, making it a cost - effective solution for feed manufacturers worldwide. Upgrade your feed granulation equipment with our superior pressure roller shell and experience enhanced productivity and product quality.

The characteristics of the full-hole pressure roller shell are as follows:

1. High-efficiency Granulation

The surface of the full-hole pressure roller shell is covered with regularly arranged holes. These holes cooperate with the inner surface of the ring die. During the rotation of the pressure roller, the material is subjected to strong and uniform extrusion when passing through the gap between the holes and the ring die, and is rapidly compressed into granules. Compared with non-full-hole pressure roller shells, the full-hole type can significantly improve the granulation efficiency of materials, reduce the residence time of materials during pressing, and thus enhance the overall production efficiency.

2. High-quality Granules

Due to the design of the holes and the uniform extrusion effect, the produced granules have good formability and uniformity. The granules are regular in shape, moderate in density and hardness, and smooth in surface. Such high-quality granules are not only convenient for storage and transportation but also more conducive to the digestion and absorption of animals, meeting the requirements of feed production for high-quality granules.

3. Wide Application

The full-hole pressure roller shell can adapt to a variety of different materials. Whether it is raw materials with high protein content such as soybean meal and fish meal, or materials with high fiber content such as straw and grass powder, good granulation effects can be achieved by reasonably adjusting the granulation parameters. This makes the full-hole pressure roller shell widely used in many fields such as livestock feed, aquatic feed, and biomass pellet fuel.

4. Wear Resistance and Durability

It is usually made of high-strength and excellent wear-resistant materials, such as special alloy steel, and undergoes advanced heat treatment processes to improve its surface hardness and overall wear resistance. Even in a long-term and high-load working environment, the full-hole pressure roller shell can maintain good working conditions, reduce wear and damage, extend service life, and reduce the maintenance cost of equipment and the frequency of shutdown for component replacement.

5. Easy Maintenance

In terms of structural design, the full-hole pressure roller shell is designed for convenient disassembly and installation, considering the convenience of maintenance. When it is necessary to clean or inspect the pressure roller shell, operators can quickly complete the relevant operations. In addition, the hole structure on its surface reduces material residue to a certain extent, reducing the difficulty of cleaning and helping to maintain the cleanliness and normal operation of the equipment.

Application of Shanbao Machinery's Roller Shells

| CPM305 | Buhler | Buhler 35 | MUZL | MUZL 1200 |

| CPM407 | Buhler 40 | MUZL 1210C | ||

| CPM3016-4 | Buhler 42 | MUZL 1610/C | ||

| CPM3016-5 | Buhler 42B | MUZL 35 | ||

| CPM3020-6 | Buhler 508 | MUZL 42 | ||

| CPM3020-6 | Buhler 508E | MUZL 42T | ||

| CPM3022-6 | Buhler 52 | MUZL 460 | ||

| CPM3022-8 | Buhler 530 | MUZL 550 | ||

| CPM7726-7 | Buhler 660 | MUZL 600 | ||

| CPM7726-9 | Buhler 900 | MUZL 600TA | ||

| CPM7730-8 | MUZL 610 | |||

| CPM7730-10 | MUZL 610TW | |||

| CPM7936-14 |

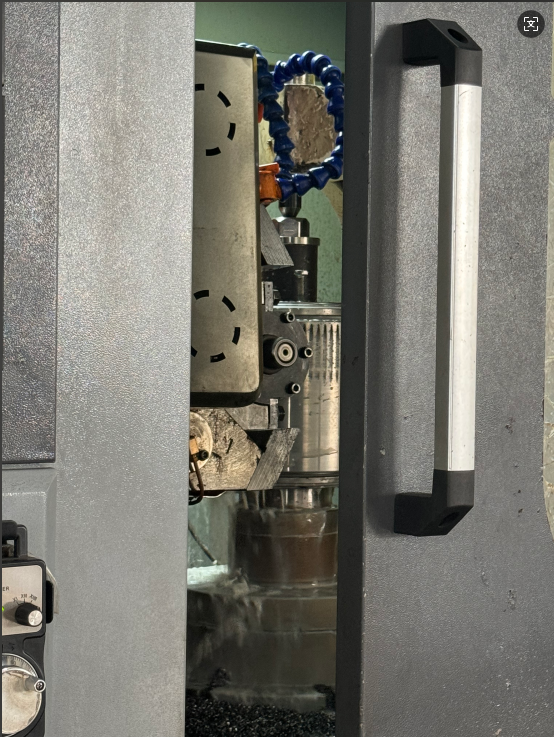

Shanbao Machinery Roller Shells process

Lathe:

Marking:

Hobbing:

Polishing:

Carburizing

Packing:

|