| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | SHANBAO |

| Model Number : | CPM 3020-6 |

| Certification : | ISO 9001 |

| Price : | $500-1000 |

| Delivery Time : | 20-30work days |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

Introduction:

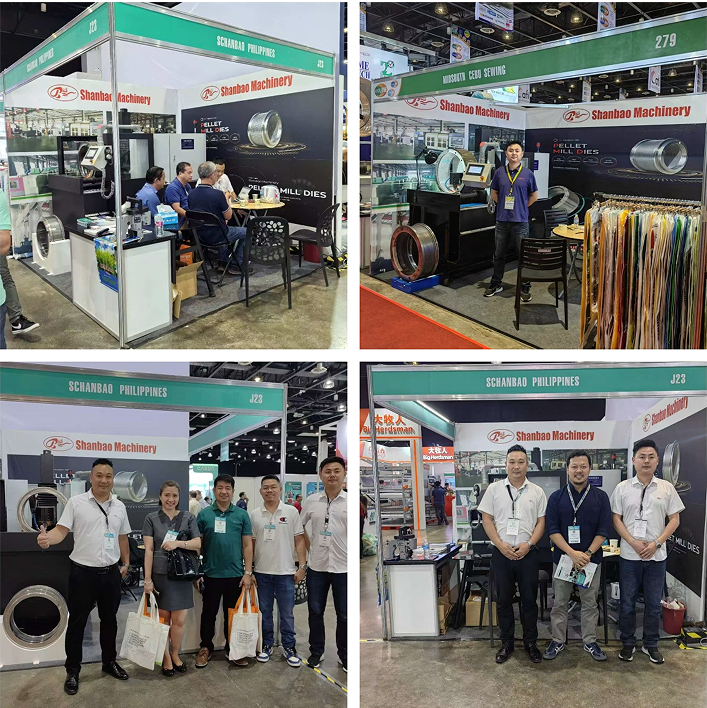

Shanbao Machinery, established in 1989, is a leading manufacturer of high-performance pellet mill dies, dedicated to helping you optimize your feed production and maximize efficiency. We are a large-scale professional feed machinery fittings manufacturer, integrating production, sales, and service. Our headquarters is located in the new zone of Meishan Industrial Park, Sichuan, China.

What Sets Us Apart:

Vertical Integration: We are the only dies manufacturer in China with our own forging and casting factory, giving us complete control over quality from the very beginning.

Expertise: Our team of 15 professional technicians boasts over 30 years of experience in machinery production, ensuring unparalleled expertise in die design and manufacturing.

Uncompromising Quality: We use premium X46Cr13 stainless steel and employ state-of-the-art manufacturing techniques to create dies that are built to last.

Hole Pattern Design:

Hole Diameter: Shanbao Machinery can customize the hole diameter to achieve the desired pellet size and meet the specific requirements of your feed material. The standard range is 1-12mm, but we can discuss specific needs beyond this range.

Hole Shape: Shanbao Machinery offers a variety of hole shapes to optimize pellet formation and reduce friction. This includes:

Straight Holes: Simple, cost-effective, suitable for softer materials.

Release Stepped Holes: Designed to prevent clogging and improve pellet flow, ideal for fibrous materials.

External Conical Holes: Conical shape helps with pellet formation and reduces friction, suitable for harder materials.

Internal Conical Holes: Similar to external conical, but the taper is inside the hole, providing additional support for pellet formation.

Hole Arrangement: The arrangement of holes within the die can be customized to achieve the desired pellet size, shape, and density. We can design custom patterns based on your specific feed ingredients, particle size, and desired pellet characteristics.

Compression Ratio:

Compression Ratio Adjustment: Shanbao Machinery can adjust the compression ratio based on your feed material, desired pellet density, and desired pellet durability. A higher compression ratio generally results in denser pellets, but it's important to consider the specific feed material and desired pellet characteristics.

Feed Type Consideration: Different types of feed require varying compression ratios. For example, feed for livestock requires a different compression ratio than feed for poultry. Our engineers can help determine the optimal compression ratio for your specific application.

Parameter:

| Raw Material | X46Cr13 |

| Type | Clamp & Screw |

| Hole Finish | Ra 0.4-1.2 |

| Hardness | 52-55 HRC |

| Blind Hole Number | 0 |

| Heat Treatment | Vacuum Heat Treatment |

| Hole’s Specification | 1-12mm |

Characteristics:

High productivity

High wear-resistance

High corrosion-resistance

High fatigue-resistance

High impact-resistance

High accuracy + Long lifespan

Production Capacity:

| Die processing equipment | Quantity |

| CNC 4 Axial gun drilling machine | 32 |

| CNC countersinking machine | 12 |

Cleaning machine for Dies | 8 |

| Vacuum quenching machine | 4 |

| Internal grinder | 6 |

| Turning-lathe | 18 |

Packing:

1. Wooden case packing

2. Pallet package

The Importance of Die Quality in Pellet Production

Target Audience: Pellet plant operators, decision-makers, and anyone involved in the pellet production process.

Focus: Explain how die quality directly impacts pellet output, efficiency, and overall production costs. Discuss the consequences of using low-quality dies, such as increased downtime, reduced output, and higher maintenance costs.

Value Proposition: Highlight how [Your Company Name]'s high-quality dies can help pellet plants achieve optimal performance and profitability.

Tips for storage Dies

The pellet dies or ring dies are the main accessory of the pellet

mill and play an important role during the pelleting.

1. The dies should be stored in a dry, clean place and marked with

the specification.

2. Suggest applying anti-rust oil if the die won't be used for a

long time.

3. Pls apply oil soak or oil boil when the holes are clogged and

then re-pellet.

4. Apply oil particles to fill the holes if the die will be stored

over 6 months.

|